Links:https://youtu.be/7rj7ipmSDGQ

| How to Maintain a CNC 4th-Axis Rotary Table? Complete Guide from Disassembly and Cleaning to Precision Inspection |

|

As automation and precision motion technology continue to evolve, the 4th-axis rotary table has become an indispensable component in CNC machining and automated production. To ensure long-term precision and stable performance, regular maintenance by the original manufacturer is essential to guarantee product quality and safety.

Take for example the 4th-axis rotary table manufactured by Herbao Machinery. This unit has operated continuously for over a decade, paired with a KUKA robotic arm in a 24/7 automated production line. After being returned to the factory for thorough maintenance and precision inspection, it continues to deliver excellent performance and accuracy—showcasing outstanding durability and product quality.

In this article, we review the complete maintenance process, from initial diagnostics to disassembly, cleaning, reassembly, and final precision verification, highlighting every detail and step of the professional workflow.

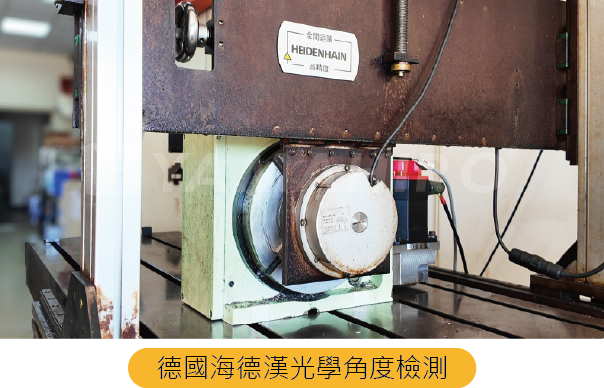

| Comprehensive Diagnostics & Equipment Disassembly The process begins with high-precision optical angle inspection using a HEIDENHAIN system to evaluate the current load and accuracy of the returned equipment. This allows engineers to analyze the condition of the unit and plan targeted maintenance. After safely removing the protective covers, wiring, and motor, the main components—including the spindle, worm shaft, worm wheel, motor mount, pulleys, and various parts—are carefully disassembled by professional technicians under strict safety protocols. |

|

Centralized Cleaning & Component Reassembly

Once all components are removed and undergo preliminary cleaning, they are placed into an automated high-pressure cleaning system with heat treatment to remove oil residue and dust. Detailed manual wiping is then performed to ensure complete cleanliness.

|

|

Critical motion components such as the spindle, worm shaft, and worm wheel are pre-assembled, followed by installation of the main housing and rotary disk as part of the initial reassembly phase.

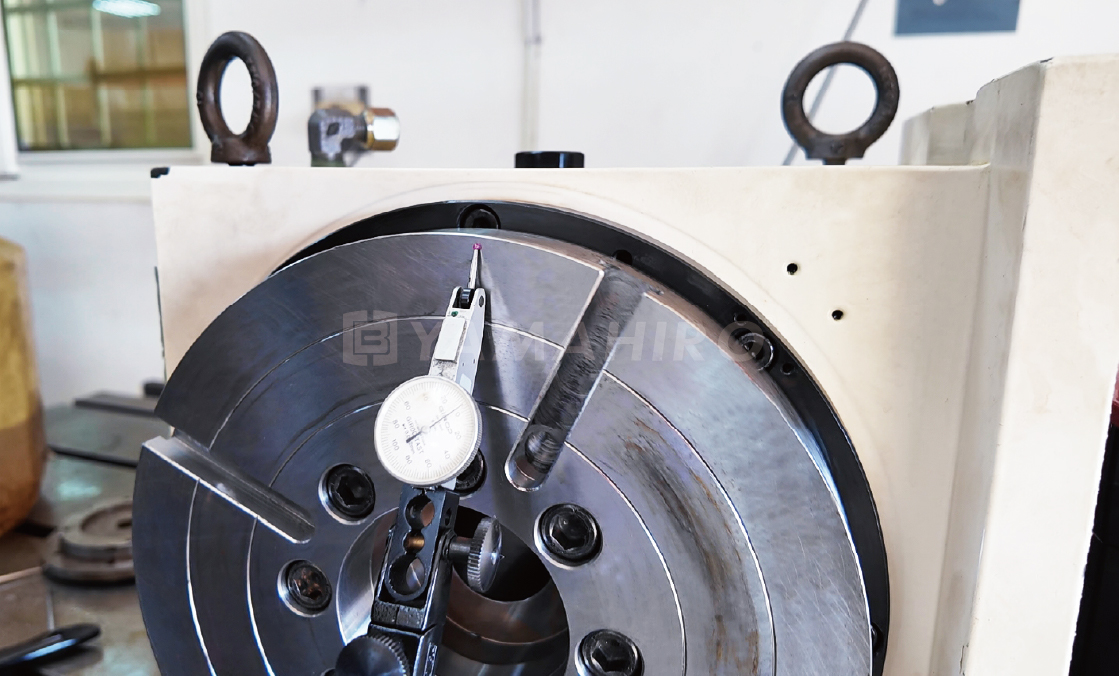

Precision Calibration & Verification

After reassembly, precision verification is performed on all rotational components—including concentricity, runout, perpendicularity, and angle positioning. These are calibrated using the HEIDENHAIN optical angle measuring device to ensure the restored equipment meets original factory standards.

Protective covers and wiring are reinstalled, and the final performance verification and functional assessment are completed before the equipment is returned to the customer.

Professional Maintenance is Key to Sustained Performance

Herbao rotary tables are engineered for durability and stability, capable of maintaining high precision even under long-term operation. With regular inspections and professional maintenance provided by the original manufacturer, equipment lifespan can be significantly extended to ensure long-term, stable production.

Herbao's service team offers factory-authorized repairs, replacement parts, and precision calibration to keep your machines in optimal condition—ensuring your production line continues to operate efficiently and at the highest quality standards.

For more insights into real-world 4-axis and 5-axis applications and technical knowledge, visit our website, follow our social media accounts, or subscribe to our YouTube channel to stay up-to-date with our latest case studies and practical insights.

( Further Reading: Rotary Positioning Table Calibration: CMM as an Alternative to Laser Inspection )

Herbao Machinery continues to pursue technological innovation, providing customers with professional and reliable solutions.

For technical inquiries or further information, please contact us!