Links:https://youtu.be/VSMFRZeBojA

| CMM Calibration for 2-Dimensional Motion Tables A Key to High-Quality Precision Positioning |

|

In precision manufacturing, rotary positioning tables are extensively used in machine tools, automation equipment, and precision machining processes. The accuracy of a two-dimensional (2D) motion table significantly impacts overall production quality and repeatability.

Traditionally, the industry relies heavily on laser measurement systems for calibration. However, in specific high-precision applications, Coordinate Measuring Machines (CMM) offer a more detailed and visual inspection method.

| What is a CMM, and why use it? A CMM (Coordinate Measuring Machine) uses contact probes or optical sensors to measure the geometric shape and dimensions of a component. It accurately captures X, Y, and Z coordinate data, effectively measuring flatness, parallelism, hole positioning, depth differences, and other critical geometric features. |

|

Why do we use CMM in addition to laser inspection?

Laser inspection provides rapid and non-contact measurements suitable for quickly detecting overall contour deviations. However, when it comes to pinpointing subtle deviations in specific positions during 2D rotational movement, especially in parallelism or perpendicularity, laser methods alone may not provide sufficient detail.

In these cases, the CMM offers another highly effective solution. With its touch probe system, it precisely measures individual coordinate points, capturing detailed data that laser methods might overlook, enabling comprehensive verification of accuracy throughout table movement.

Herbao Machinery’s Rotary Table CMM Calibration Procedure

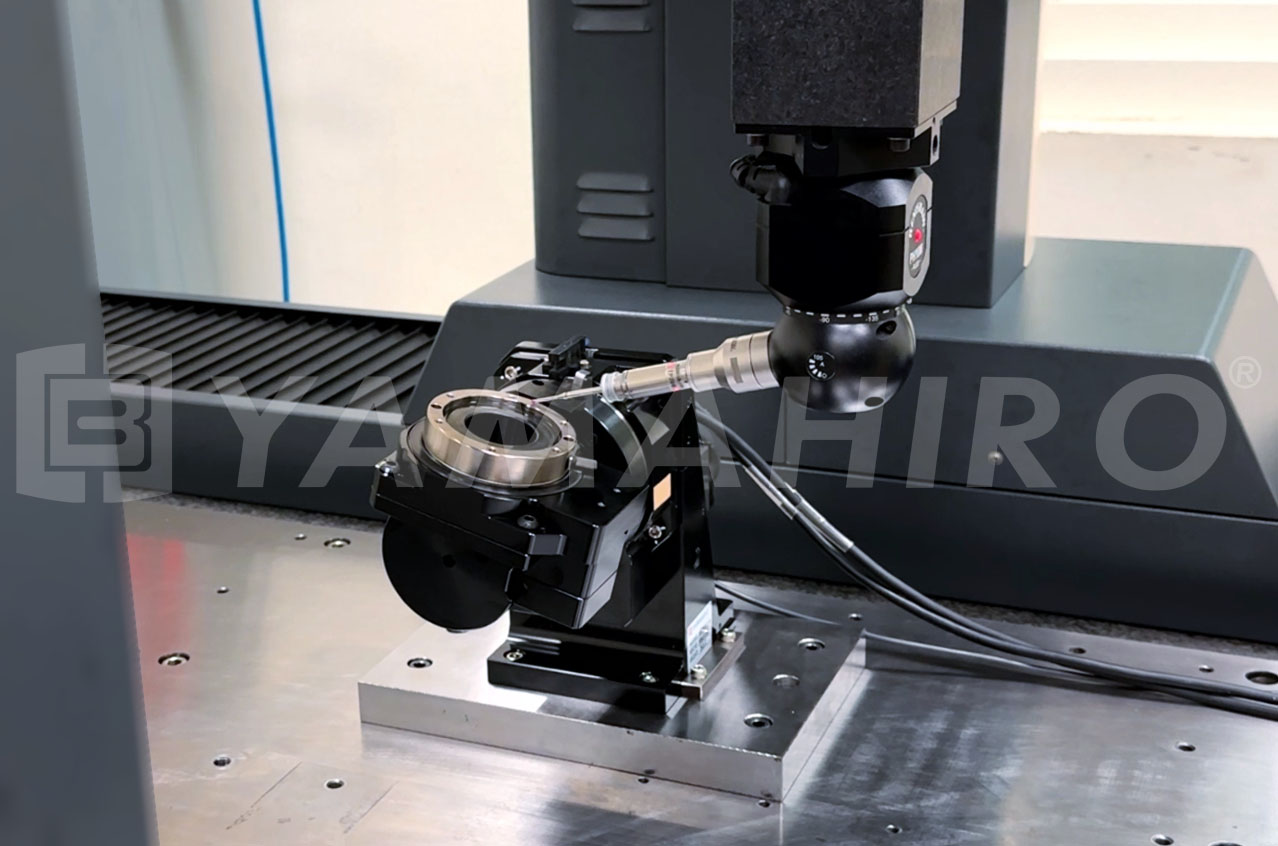

Step 1: Equipment Setup and Establishing Reference Points

The rotary positioning table is firmly mounted on the CMM’s measuring table. Reference points are established to ensure consistent and accurate subsequent measurements.

Step 2: Probe Positioning and Initial Calibration

A highly precise measuring probe locates and records the established reference points on the table’s surface, generating an accurate baseline data model.

Step 3: Sequential Angle Measurement

The table is incrementally rotated, typically by 15 degrees per step. After each rotation, the probe measures again, comparing the targeted angle against actual measurement data to verify rotational positioning accuracy.

Step 4: Real-time Data Analysis

Measurement data is instantly relayed to the computer, where software analyzes precision, ensuring parameters such as flatness, perpendicularity, and concentricity remain within permissible tolerances.

Step 5: Comprehensive Data Reporting

Upon completing all angle measurements, the CMM generates a detailed inspection report, which serves as a key reference for quality control and analysis, ensuring that the rotary positioning tables consistently meet the highest standards.

|

Real-World Applications The accuracy of two-dimensional motion tables is critical in industries such as high-precision component manufacturing, PCB drilling, semiconductor packaging, and medical device production. For instance, automated alignment and bonding systems operating without stringent calibration may result in slight inaccuracies, significantly increasing production line defect rates. |

Conclusion

The introduction of CMM measurement technology not only enhances the reliability of rotary positioning tables but has become a crucial verification method in the precision machining industry. Herbao Machinery employs this technology to effectively ensure equipment quality, providing industry users with increasingly precise and stable solutions.

Video Demonstration

Herbao Machinery continues to pursue technological innovation, providing customers with professional and reliable solutions.

For technical inquiries or further information, please contact us!